A Successful Season in the Antarctic

SSEC’s Ice Drilling Design and Operations (IDDO) group had a spectacular season in Antarctica this past year.

Back row from left: Nicolai Mortensen, Paul Sendelbach, Josh Goetz, Elizabeth Morton, Mike Jayred, Jay Johnson, Krissy Dahnert. Front row from left: Chuck Zander, Chris Gibson

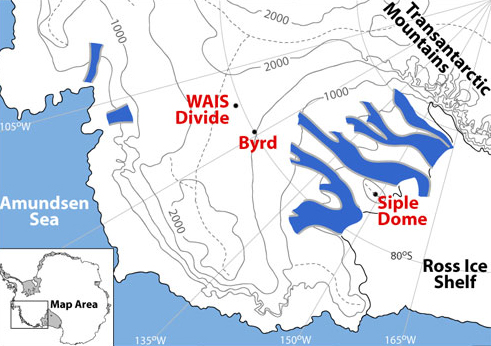

Record Depth (and Project Completion) at the WAIS Divide

On 31 December 2011, the Deep Ice Sheet Coring (DISC) drill reached a depth of 3405.077 meters (11,171.5 feet). Developed by engineers of IDDO, the drill broke the previous record of 3331 meters set by the team the previous February. The precision drill also set records for the quality of ice core retrieved.

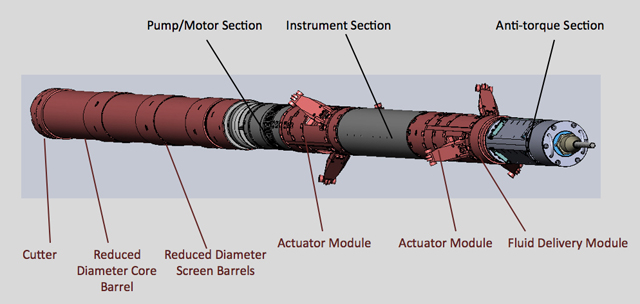

The DISC drill is a tethered mechanical drill system, essentially a rotating hollow tube with four razor-sharp blades at its cutting end. The drill is designed to retrieve cores of ice from depths of up to 4,000 meters, the limit of its suspending cable.

The actual hole is 35 feet below the floor of the building. The drill is tilted via a crane into the hole and then is supported by the cabling all the way down.

The ice cores produced by the DISC drill are 12.2 cm (4.8 inches) in diameter and up to 3.5 meters long. Deep inside the glacier, the pressure of the incredible weight of the overlying ice pushes on the borehole at all times, threatening to collapse it and trap the drill. Consequently, the shaft is filled with a fluid which provides the hydrostatic compensation necessary to prevent closure.

Suspended in the ice cores slowly winched up from below are millions of tiny bubbles – ancient air that was trapped when the snow fell millennia ago. At the 3,400 meter mark, the ice (and the air trapped within it) is approximately 55,000 years old.

“Think of these cores as a giant library of ancient weather reports,” said Principle Investigator and Professor Emeritus Charles Bentley. “The scientific community decided what they needed for a new drill. They wanted lots of new capabilities. Their requests drove our design team and the result was the DISC drill.”

The location of the WAIS Divide drilling site. The nearest base is 100 miles away. All personnel and equipment are flown in via LC-130 aircraft.

The West Antarctic Ice Sheet (WAIS) Divide ice core project integrates over 40 separate but complimentary projects that analyze ice cores for ancient climate data. Ice cores taken from this area will enable direct comparison to equivalent cores taken in Greenland, tying together climate studies of the Northern and Southern Hemispheres. WAIS ice cores have far less dust than the Greenland cores, allowing unprecedented precision and resolution for measuring greenhouse gases in the paleo-atmosphere.

Replicate Core Drill Testing

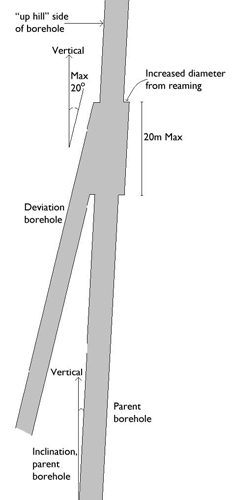

Once the main borehole was completed, the IDDO crew spent the remainder of the season testing the replicate coring subsystem of the DISC Drill. This new subsystem is designed to allow core to be collected in branches off the main borehole using directional drilling techniques.

The borehole will be used as a gateway to additional core sampling. The replicate core drill is designed to slightly alter its course and angle its way out of the main bore hole, creating a second path at any desired depth in the ice, and collecting multiple samples from the same strata.

Replication drilling has been tried before, but this is completely new technology. Previously, branch holes were effected with a wedge or a block of wood stuck into the borehole deflecting the drill. The drill would take the path of least resistance, deviating out through the “downhill” side of the slightly slanted borehole (sometimes as much as 6 degrees off plumb). Subsequent drills would tend to follow gravity and drop into the new hole.

The IDDO engineers have solved that problem with actuators along the shaft of the drill which apply lateral pressure against the side of the borehole, slightly altering the orientation of the drill head. A new borehole is started and, within about 30 meters of drilling, becomes a unique and separate path. Each actuator arm can push out up to 200 pounds, providing the thrust for the creation of the second path.

If a scientist desires additional ice from the same depth for continued study, the replicate drill can supply as many as five separate holes for more coring. As many as 200 additional meters of ice core can be retrieved from essentially the same depth.“The actuators enable us to exit the borehole on the uphill side,” SSEC Engineer Nicolai Mortensen says. “We can work counter to the pull of gravity and then be able to use the path deviation again and again to collect more samples.”

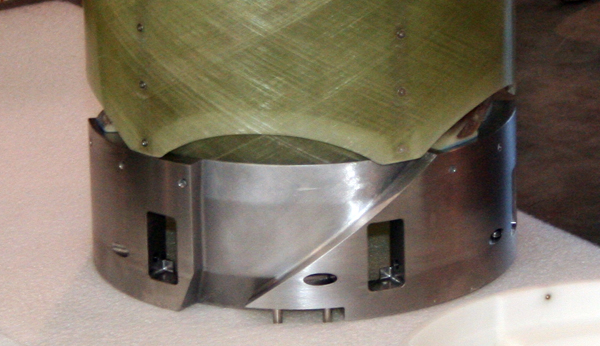

The drill descends through the previously bored hole at one second per meter. The drill has a rotating barrel and cutting head with 4 teeth on it. When the turn of the drill is reversed, teardrop shaped “core dogs” etch into the bottom of the ice core and break it off for retrieval.

While the shortness of time available to conduct the testing this season did not allow for the collection of any cores, a great deal was learned. The replicate drill is expected to hit the ice fully operational at the beginning of December 2012 and successfully collect replicate cores during the 2012-2013 field season.

The IDDO crew involved in the WAIS Divide Project included lead drillers Jay Johnson and Kristina Dahnert and SSEC engineers Nicolai Mortensen, Chris Gibson, Josh Goetz, Paul Sendelbach and Chuck Zander and contract drillers Elizabeth Mortensen and Mike Jayred.

Blue Ice Drill and More

Former IDDO Engineer and current contract driller Tanner Kuhl completed coring of “blue ice” on Taylor Glacier in Antarctica during the 2011-12 field season. He used the IDDO designed and constructed Blue Ice Drill (BID), which is capable of collecting 9.5-inch diameter cores to depths of 15 meters, recovering over 900 meters of core.

Developed specifically to take samples from blue ice – a dense, extremely hard ice formed deep under the Antarctic ice sheet by the incredible pressure of hundreds, even thousands, of meters of ice above it. If a flowing glacier meets an immovable geological structure, such as a mountain, the blue ice at the bottom of the glacier can be forced to the surface. As the years pass, the oldest ice in the glacier is exposed to the light, and to researchers’ drills.

The Blue Ice Drill rig is easily transportable, enabling quick set-up for multiple core extractions.

One of the challenges facing the IDDO team was snapping the core of super-hardened ice off of its parent glacier at depth in a narrow, confined bore hole. A second piece of equipment, the Core Recovery Drill, is sent down into the hole where a piston on the side of the recovery tool drives the sample horizontally. The core was melted on site by the science investigators to measure trace gases trapped in the ice.

IDDO also provided a small hot water drill for two seismic studies on Whillans Ice Stream. The investigators, using the drill, drilled over 280 shot holes and collected more than 9 km of seismic data.

A Very Successful Season

All of this was accomplished in a season with a greater than average number of storms – one every three to four days, with blowing snow and poor visibility. But there were no lost days due to weather and no reportable injuries to any of the crew all season.

An excellent antipodal “summer” at the bottom of the world!

Professor emeritus Charles Bentley inspects the barrel of the Blue Ice Drill, designed and built by the UW-Madison IDDO team.