Reflections on a 50-year career, draftsman Tony Wendricks looks back

Tony Wendricks recently retired from the University of Wisconsin-Madison Space Science and Engineering Center (SSEC) after a career that spanned a half-century. During his time at SSEC, from draftsman to project coordinator, he crossed paths with almost every instrument and research program and the scientists and engineers who managed them. Recently, he sat down to share some of the highlights.

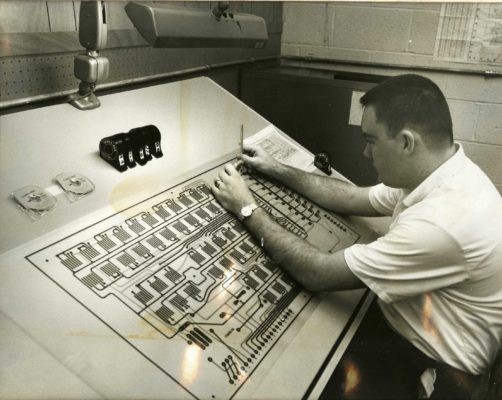

Tony Wendricks working on McIDAS circuit board drawings at SSEC, early 1970s. Credit: SSEC.

SSEC: Talk about your early days at SSEC as a draftsman.

TW: I started here as a young guy in 1967 and my boss during those years was Leo Skille, the chief electronics technician. Leo helped me navigate around SSEC and became a role model to me on how to be a good mentor.

I was a draftsman, then a drafter (when the title became gender-neutral), then a computer aided design (CAD) specialist, and then I became a bridge from the department to the various shops when we started outsourcing some work – I was able to translate between the engineers at Space Science and the vendors. Space Science gave me these opportunities along the way: opportunities that were always supported by Leo Skille.

I was a draftsman for nearly every project at SSEC because every project needed drawings. Before computerization, engineers would do the design and then the draftsman would make those drawings legible. This was important especially if the design had to be reviewed or built by someone else. This was a critical role.

When I came here, there was no drafting department, so I really had the opportunity to establish it. I got what I wanted! Space flight projects were a big deal then and things – including money — flowed. It was an exciting time to be involved here.

SSEC: What were some of your first projects and how did your role change over time?

TW: The first project I worked on was the TIROS-M [which became ITOS-1] flat plate radiometer. All of this work was done at SSEC. Since I was the only draftsman, I got to make the mechanical drawings, but I had no clue about how to do the electrical drawings. Because of the environment here, and the people I was working with – they brought me up to speed on resistors and capacitors.

Then, when they started to design circuit boards, we started building them here, too. They needed a physical layout, and I learned how to draw those. There were boards for many projects and instruments, but the early work was for McIDAS (Man-computer Interactive Data Access System).

And once the project work was concluded and scientists and engineers were ready to publish about their results, I did the drawings for publications, too. We provided complete drafting services and this occupied quite a bit of my time.

There was lots of energy here. Because there were limited numbers of people, most of the time everyone was involved in the project. So when the project ended, there wasn’t always something to immediately replace it.

During one of those lulls, I actually took another job – I wasn’t seeking it – but Stan Sitz, who had been an SSEC electronics technician, contacted me because they needed a draftsman at the company where he worked.

Things were a little slow at SSEC at the time, and Stan had left. It was really on a lark that I went to the interview – I did it mostly just to stay in touch with interviewing. They wanted me because I had set up the drafting department here. After I’d been there for six months (June-December 1974), I called SSEC to find out how I could get my money out of the retirement fund. During that phone call, Mary Maynard in human resources (who was also married to Jim Maynard, another SSEC electronics technician) told me that a big project was coming up and they needed a draftsman.

Mary told me to think about it over the weekend. Well, when I considered my current long commute on the old, two-lane beltline, and added a few things up, I went back to SSEC and left my retirement fund alone. It was the best decision I ever made.

When I came back, the big project was the Hubble Space Telescope. The High-Speed Photometer (HSP) was built by SSEC and included on the Hubble Space Telescope when it was launched in 1990. [The HSP was replaced early in the mission with COSTAR (Corrective Optics Space Telescope Axial Replacement) in order to correct a problem with the primary mirror for the remaining instruments].

I worked on the HSP drawings for years. But at the same time, McIDAS was also in full swing. While McIDAS was moving forward, the world of drafting was changing, too. We were becoming CAD specialists.

Sometimes it was painful to make a drawing with a computer. You could make a schematic, but you had to have good graphic design skills in order to do the layouts. All of this evolved so fast, as computers evolved – pretty soon we were doing the printed circuit layouts, and this saved huge amounts of time. Before long, as the software improved and the systems kept getting stronger, we could make 3-D renderings.

I worked on lots of McIDAS iterations, the high spectral infrared sounder (HIS), and many other projects during the 1980s. We hired Nick Ciganovich as a draftsman when it became obvious there was more work than I could manage myself.

SSEC management asked me what to do and I told them to hire the best person and that I would take on the parts of the job that they could not do. Nick was good at mechanical renderings and they couldn’t have made a better choice. So Nick did the mechanical drawings and I was happy to do the other work – it was a great split.

This was a very open-minded approach to hiring, which was the way SSEC did things: hire and keep the best people. SSEC has always been about good people.

When McIDAS was going strong, there were schematics like you would not believe. There was so much work, that we hired a third person, John Short, plus about six students.

Over time, as computers became more sophisticated, some of the engineers and scientists started doing their own drawings. But that never stopped anyone from reinventing themselves so that they remained useful. I had the opportunity to do that – over and over.

SSEC: What are some of the most memorable moments of your time at SSEC?

TW: I remember there was a group of us that included Ken Walker, Stan Stiz, Jim Maynard, Bob Oehlkers, Leo Skille, Gene Buchholz, and me took shifts guarding the building during several weeks in 1970, around the time of the Sterling Hall bombing. We were on edge during that time because there were demonstrations that sometimes came down Dayton Street. All of the first floor windows were boarded up except for the office right behind the first window and that became our lookout post. Later, it was disclosed that the Army Mathematics Research Center’s computer had been moved to our basement for safekeeping! We didn’t know this at the time.

Another challenging moment was when we finished up with the Adiabatic Demagnetization Refrigerator (ADR) or salt pill. The ADR was flown on the Astro-E satellite, [a joint Japanese-NASA X-ray astronomy project[ and was used to cool one of the satellite’s X-ray detectors.

When we completed work on it, I was asked to carry it through the airport, on the plane, and deliver it in person to NASA’s Goddard Space Flight Center. This was after 9/11, so security was tight. Mark Mulligan, the principal investigator wrote a letter that was signed by Hank Revercomb, the director at the time, to airport security explaining the purpose of my trip. Mark also contacted the airport in advance so that they knew I was coming.

It was the size of a 20 ounce beer can, but it had to be refrigerated, and because it was space flight hardware, the engineers wanted to be sure it was handled carefully. It could have been a pipe bomb, for all they knew, but it went smoothly because of the letter and announcement.

In the 1990s, I had the opportunity to design the patch for NASA’s DXS mission. The Diffuse X-ray Spectrometer instruments, which were built at SSEC, were flown on the STS-54 mission of the Space Shuttle Endeavour in January of 1993. Everyone who was part of the mission wore that patch on their uniforms and even today, an 18” by 24” version of the patch hangs at Mission Control in Houston.

DXS patch designed by Tony Wendricks.

I would say that all of the Antarctic trips were highlights, along with the experience of working with the Antarctic drilling crew. They stand out because it’s Antarctica, after all. I’ve heard a lot of people say that the first time you go you wouldn’t need to be paid to go, and I feel the same way.

Well before my first trip, we got the drilling contract from the National Science Foundation, but even before that, in November of 1999, Bob Paulos was in his office writing a proposal and needed to create an organizational chart for the team. He called me in one day and asked if I wanted to be part of the team, and I said yes. And then I asked what I would have to do! They called me a project coordinator which involved making sure that we received all drill systems from the University of Nebraska, who had the contract at the time.

We needed to get all of the drilling equipment from them, but first it required that I go to Nebraska to inspect the equipment. I had no idea what I was looking at, but a man named Bruce Koci, who had been in the drilling business for a long time, went with me. Bruce was not your average individual – great driller – he had more intuition about ice drilling than anyone. Bruce and I went and looked at the stuff and determined what we would take and would not take. And that’s how we got all the equipment.

And then, I had to make sure that projects got staffed, so when I was in Nebraska, I asked them about their drillers. Jay Kyne was mentioned, as someone who we should see if we could get – he came with us. He was to go on our first project to Tibet and then the Antarctic. I went along, and we took a core and air samples at the South Pole in January 2001. It was my first trip.

It was life changing. All of a sudden I became someone who had been to the Antarctic. A lot of people wanted to know about it – teachers wanted me to talk to their classes, my brother arranged Kiwanis presentations. I can’t tell you about all of the presentations – they still want to know, even though it’s about 17 years ago. It’s pretty neat.

So, when I first gave those talks, I was a little self-conscious, but a little old man came up to me after that first Kiwanis meeting and said, “I am probably too old to go there, but I feel as though I’ve been there today, with you.” All of my anxieties disappeared after that.

I realized that it was all about the Antarctic; and not about me. It has, to some degree, changed who I am. These experiences, and Space Science, have molded me into the person I am today.

Tony Wendricks at the South Pole. Credit: SSEC.

SSEC: What is your favorite story about SSEC?

TW: My favorite story – and my proudest moment – is mentoring a young person at SSEC, as Leo Skille had done for me. Her name is Krissy Slawny. She has earned her place at SSEC, but I like to believe that I was her biggest cheerleader. I hesitate to use the word promoted, but I promoted her to the people who could make decisions about her future. Why? Because from day one, she was doing the job – whatever it was – and excelling at it.

She started out as a student worker on the loading dock, but very soon expressed an interest in going to Antarctica. I told her, “Krissy, be careful what you wish for.” And I thought that was the end of that conversation.

But she continued to express the same interest – I tried to tell her about all of the challenges of going there, but she persisted. So I added her name to my list — a list that I maintained as project coordinator. Any time we had a big project, I sent out a mass mailing asking if anyone wanted to go. This was the same process we used for landing many of our excellent drillers for the ice coring and drilling program.

Eventually, she got chosen. And she excelled, which was no surprise. Krissy got on the crew for the first year, and the second year she was the assistant lead on the drilling team.

After she graduated, we looked for something to keep her at SSEC. It ended up being quality assurance – she was not too thrilled with that assignment, but I assured her that it was a stepping stone, never really realizing how far she would actually go.

Charlie Bentley said the same thing about Krissy: she excels at every level.

When we got busy enough that we needed a field project manager, Krissy was brought on to do that, and did it twice as well as I ever had. She was so organized and had such great rapport with everyone. Don Lebar was the program manager at the time. When he would go on vacation for several weeks at a time, he would prepare Krissy, me, and others for everything we might need to know while he was away. Krissy stepped up and took on the role so effortlessly. When Don came back, I made it known to people in decision-making positions, like John Roberts, that Krissy had done such a great job during Don’s absences.

The rest is history: Krissy is now the principal investigator and program director for the Ice Drilling, Design and Operations program at SSEC.

I think this is my proudest moment.